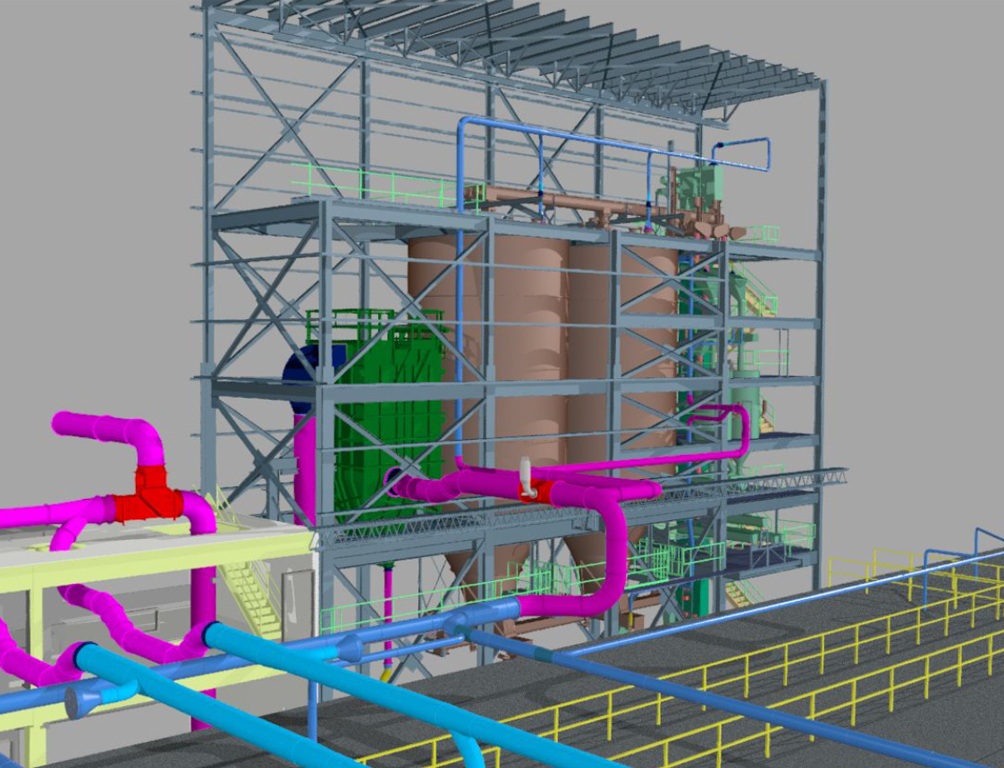

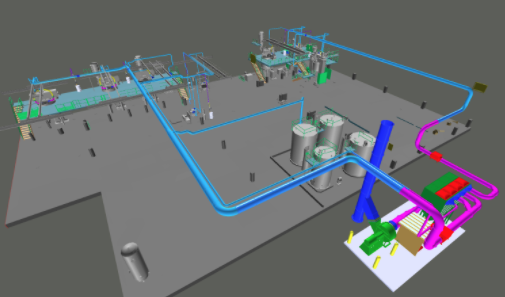

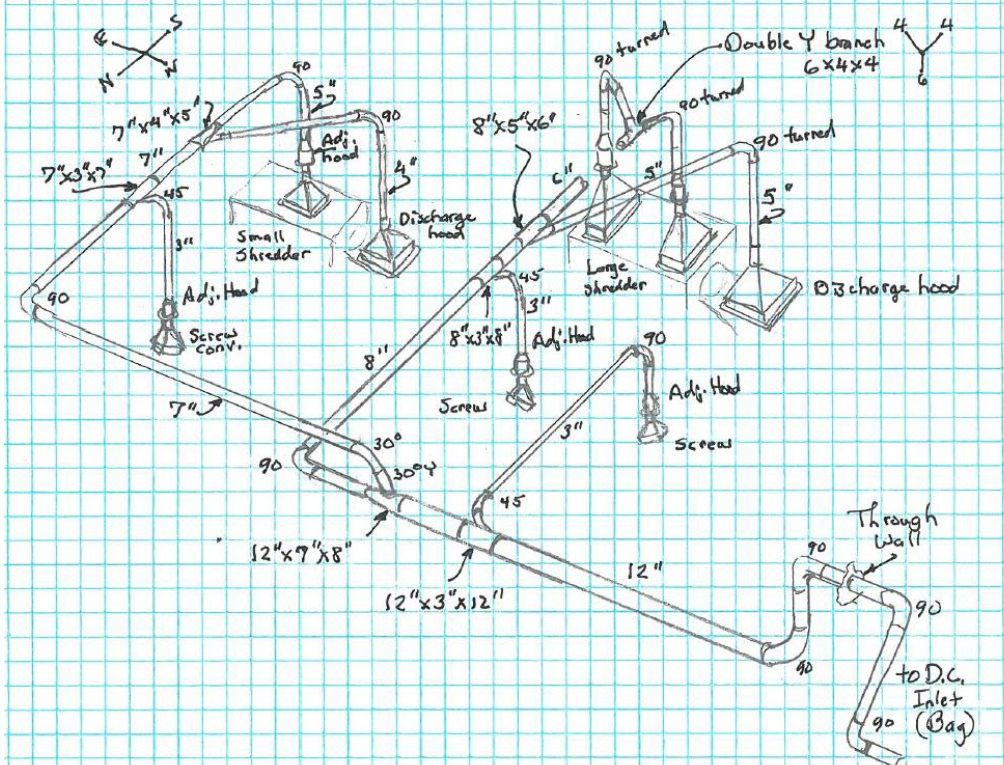

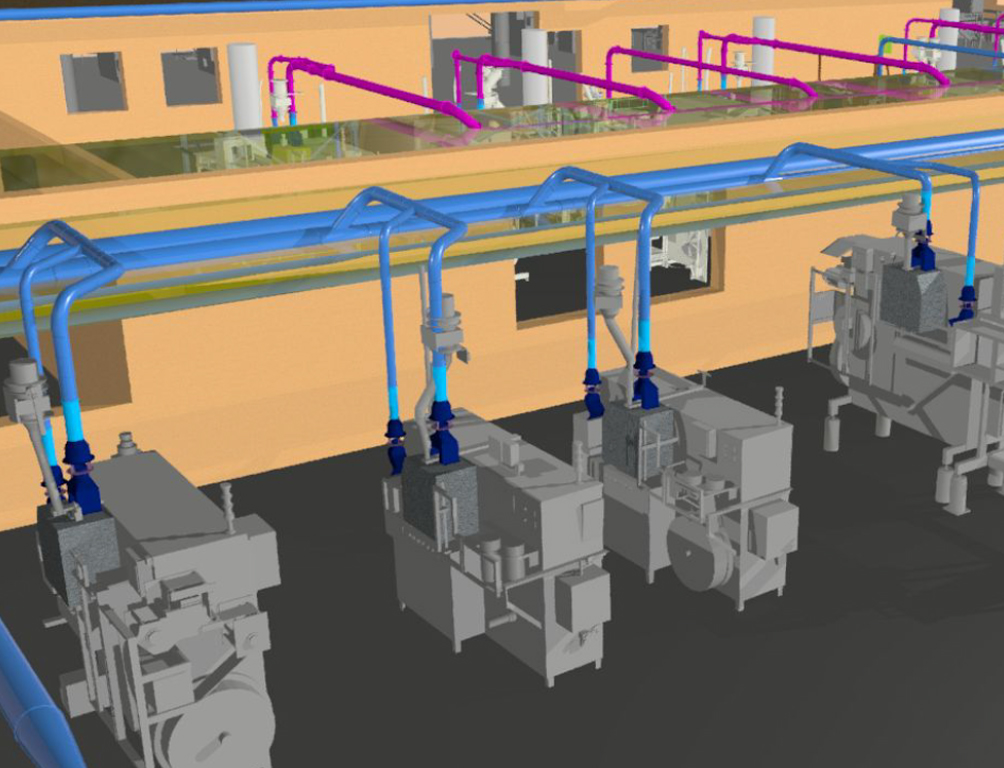

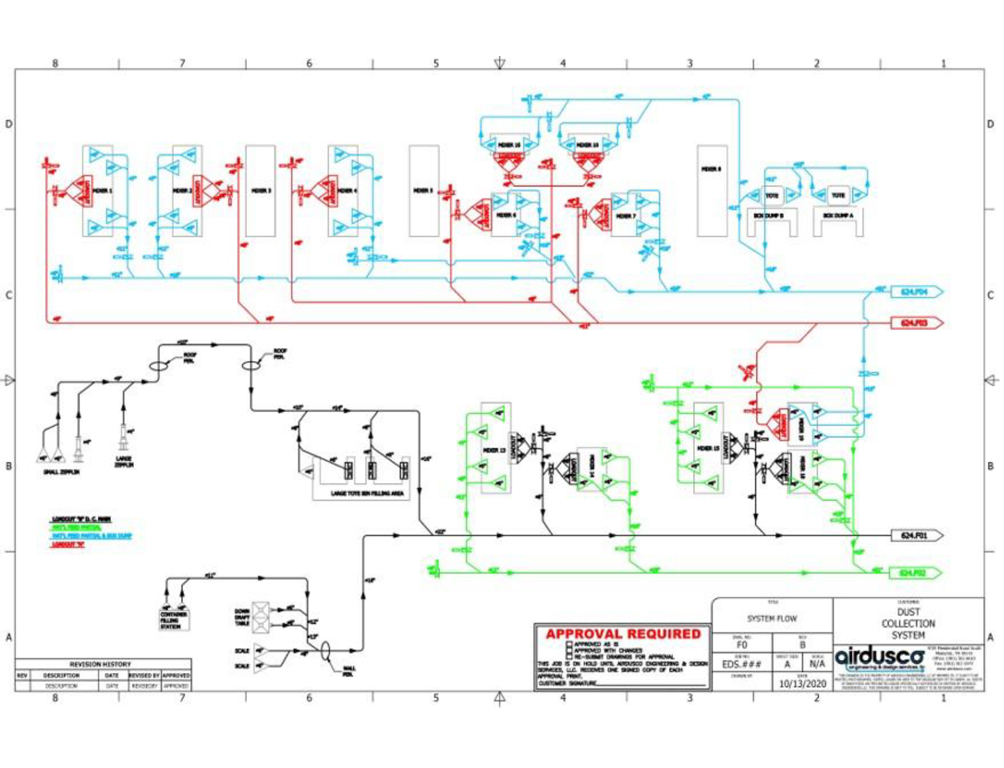

Our team of experienced engineers and AutoCAD designers will design your dust collection system to provide proper operation and meet regulatory compliance in accordance with the Industrial Ventilation Manual and NFPA Guidelines.

Too often engineering firms want to use a “clean-slate” approach for solutions to an existing problem.

Other times manufacturers of equipment will offer to do system design with the goal of selling more equipment, whether it is needed or not.

Airdusco EDS uses a different approach that we believe is more cost effective for the customer. We seek first to optimize the existing system and to utilize the existing system and main equipment as much as feasible. Only if the system is incapable or a hazard exists that cannot be corrected, do we propose major changes.

© Copyright – Airdusco Engineering & Design Services, LLC. All rights reserved. Powered by LAB Digital Creative